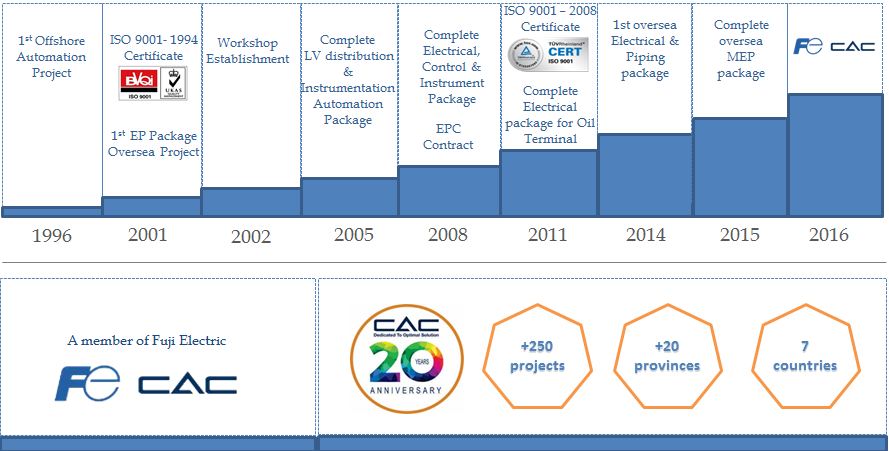

Since the establishment in 1995, Fuji CAC has been writing our story of success. Starting as an electrical, automation and instrumentation service provider, Fuji CAC has grown to become one of the most reliable and respected engineering, procurement, construction and maintenance contractor for multiple business sectors in Vietnam and South East Asia countries.

- The first Vietnamese company supplied and engineered automation system for offshore oil-rig (VietsovPetro, 1995).

- The first Vietnamese company successfully researched, designed and built NPK fertilizer production line and exported to African market (Ivory Coast, 2000).

- The first Vietnamese company successfully acted as EPC Contractor to build a complete Cement plant (NamSon, 2008).

- The first Vietnamese company was awarded MEP package as main contractor to build new plants of CocaCola in Vietnam, Myanmar and Cambodia (2013, 2014 & 2015).